Mandi Gobindgarh, Punjab, 147301

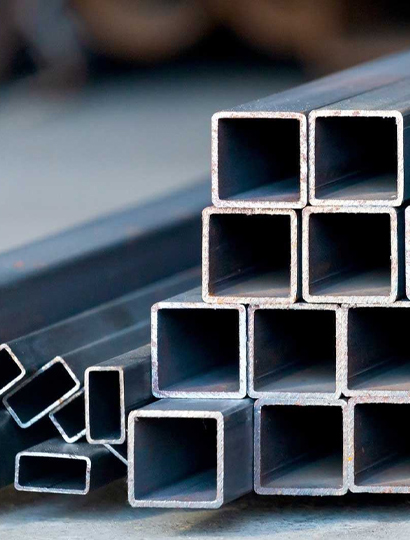

ERW Square Pipes

Our Products

ERW Square Pipes

Vardhman Alloys is a premier manufacturer of Electric Resistance Welded (ERW) square pipes, known for their exceptional quality and performance. As an industry leader, Vardhman Alloys combines advanced technology with rigorous quality control to produce ERW square pipes that meet the highest standards of durability and reliability. ERW square pipes from Vardhman Alloys are designed to cater to a wide range of applications across various industries. These pipes are widely used in construction and infrastructure projects for structural support, framing, and scaffolding.

ERW square pipes from Vardhman Alloys are designed to cater to a wide range of applications across various industries. These pipes are widely used in construction and infrastructure projects for structural support, framing, and scaffolding. Their robustness and precise dimensions make them ideal for use in the fabrication of machinery, automotive components, and equipment in the agricultural and industrial sectors.

Specification

| Thickness | 1 - 3 mm |

|---|---|

| Shape | Square |

| Brand | Vardhman Alloys |

| Material | Mild Steel |

| Size | 1/2 inch, 1 inch, 2 inch, 3 inch, 4 inch, >4 |

| Color | Steel , Black |

Working Process Of ERW Square Pipes

- Raw Material Selection: The process begins with the careful selection of high-grade steel coils, ensuring they meet the required chemical and mechanical properties for ERW pipe production.

- Slitting: The steel coils are slit into narrower strips of the desired width using precision slitting machines. This step prepares the strips for forming.

- Forming: The slit steel strips are passed through a series of forming rolls to shape them into a cylindrical form, a necessary step before welding.

- Welding: The edges of the cylindrical strip are heated using electrical resistance and then pressed together to form a continuous weld seam. This ensures a strong, uniform weld.

- Sizing and Shaping: The welded pipe is passed through a series of sizing rolls to transform it from a round to a square shape, ensuring precise dimensions and uniformity.

- Cutting: The continuous length of the square pipe is cut to the required lengths using a flying cut-off machine, ensuring consistent and accurate pipe lengths.

- Heat Treatment: Depending on the specifications, the pipes may undergo heat treatment processes such as annealing or normalizing to enhance mechanical properties and relieve internal stresses.

- Surface Treatment: The pipes are subjected to surface treatments, such as pickling, galvanizing, or coating, to improve corrosion resistance and surface finish.

- Inspection and Testing: Each pipe undergoes rigorous inspection and testing, including non-destructive testing methods like ultrasonic testing and hydrostatic testing, to ensure quality and structural integrity.

- Marking and Packaging: The pipes are marked with relevant specifications and securely packed for transportation, ensuring traceability and protection during transit.

Applications

- Construction and Infrastructure: Structural support in buildings, bridges, and other infrastructure projects. Framework for metal buildings and structures. Scaffolding, fencing, and railings.

- Automotive Industry: Components in vehicle frames and chassis. Roll bars and protective structures. Exhaust systems and other automotive parts.

- Mechanical and General Engineering: Fabrication of machinery and equipment. Conveyor systems and material handling equipment. Frames and supports for various mechanical applications.

- Furniture Manufacturing: Frames and structural components for furniture. Outdoor and indoor furniture designs.

- Agriculture and Irrigation: Structural components for agricultural machinery. Irrigation systems and equipment. Greenhouse frames and supports.

- Oil and Gas Industry: Piping systems for oil and gas transportation. Structural components in refineries and processing plants.

- Power and Energy: Structural supports in power plants and renewable energy installations. Piping systems for various energy applications.

- Telecommunications: Support structures for antennas, satellite dishes, and communication towers. Poles and towers for telecommunication lines.

- Marine and Shipbuilding: Structural components in shipbuilding. Piping systems for ships and offshore platforms.

- Industrial Applications: Piping systems in factories and industrial plants. Structural supports and frames for industrial equipment.